Rotating Print/Cut Tool with Registration Applications

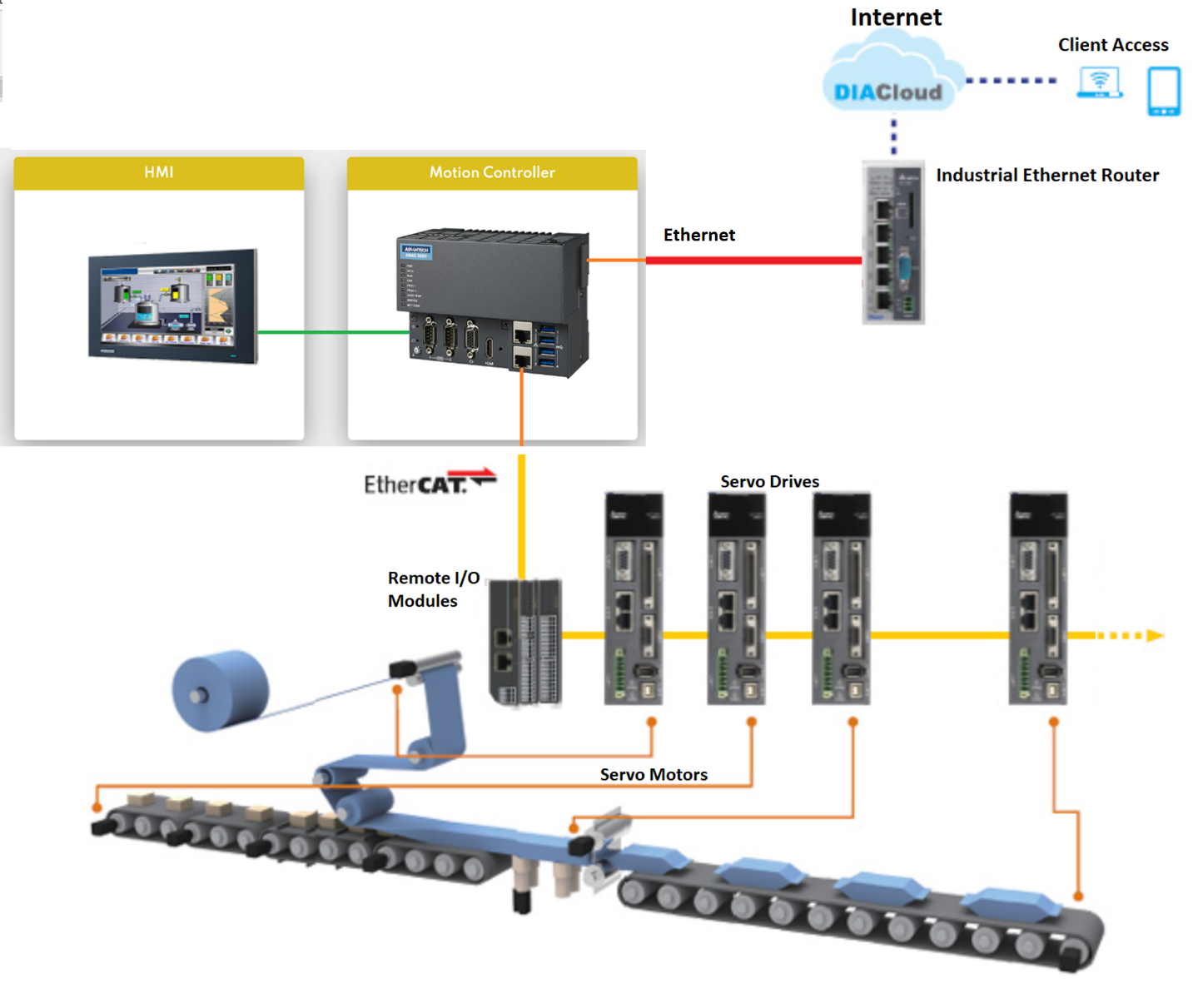

Web handling with registration applications include the following main components (Fig. 1, Fig. 2, Fig. 3):

- HMI as the human machine interface device

- PLC/Motion Controller as the machine controller

- Master Encoder (or a Servo motor with encoder)

- EtherCAT Slave Module for Master Encoder interface

- Slave Servo Motor for the tool axis ( print head or a cut head ) which follows the Master Encoder in order to match the speed of the web.

- Registration mark sensor

Fig. 1- Web handling machine with rotating knife: master axis is encoder which measures web speed and position. Slave axis is the knife axis which is electronically geared to Master axis and has registration mark sensor based motion correction.

The key motion coordination requirement in web handling applications is that during the period during which the web and tool are in contact (contact phase), the tool (cutting knife, print head, sealing head, etc.) must be moving at the same linear speed as the web. When there is no contact between the tool and the web (non-contact phase), they don’t have to match the linear speeds. In addition, the application may require “registration”, which means that during the contact-phase, the position of the tool with respect to web must be accurate relative to a mark on the web. For that purpose, there is a “registration mark sensor” which is used to make position corrections to make the relative positions accurate despite imperfections in the process.

Fig. 2 – Packing machine application: web moves in electronically geared mode with the product on conveyor, including registration motion correction, to make a package around a product. The system involves four axis servo motion control: two servos (one for each) for two conveyors, one web motion (electronic gearing and tension) and one for sealing/cutting station. All are EtherCAT compatible servo drives and motors. Motion controller with EtherCAT Master role controls the servo motions, communicates with HMI and Internet thru Ethernet.

Fig. 3- Commercial printing machines have web as the master motion reference axis, and every station is electronically geared as Slave axis, some stations with registration sensor.

When the tool is in contact with the web, the linear speed of the tool and the web must be the same. When they are not in contact, they must move in a gear ratio dictated by the distance the two axes must move during the non-contact phase. Some printing heads print through the whole circumference of the print cylinder. In that case, the linear speeds must always be matched. The whole cycle is a contact phase and there is only one gear ratio.

For instance, in paper cutting machines, the flying knife can be geared to the master axis moving the paper (Fig. 4). The paper must be cut at certain length and at a certain offset distance from a registration mark. The paper may slip (or stretch due to temperature or tension variations) in the master axis drive. As a result, the master encoder reading of paper movement cannot always be perfect. To correct for such unavoidable problems, a registration mark is always sensed on the paper at a fixed distance from the cutting point. Regardless of the source of the error (i.e. printing error of the mark position or master encoder accuracy loss due to slippage), there has to be a fixed phase relationship between the cutting knife and the position of the registration mark on the web.

When the tool is not in contact with the web, the tool speed can be adjusted in order to let the proper amount of web distance pass. If the design was not a programmable motion control system and it was mechanically geared, a rotating knife machine could only cut one paper length only which is the length of the knife circumference. The ability to program the motion of the knife so that while it is in contact with the web it matches the linear speed for a correct straight cut, and speed up or slow down while it is not in contact with the web, provides us with the capability to cut many different lengths of web with one rotary knife. The same discussion applies to print heads and sealing head applications where the cycle length for which a new print or seal is to be made can be programmed.