Motion Control Solutions

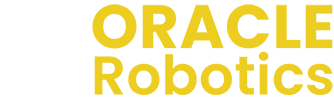

There are five major component groups in a state of art motion control system as follows:

- HMI Device: any smart device (Laptop PC/MAC/Tablet/Smart Phone) with web browser capability or OPC/UA capability, or just a monitor.

- Motion Controller based on EtherCAT and CODESYS. Hardware is based on industrial PC bus hence leverages the economies of scale in hardware.

- EtherCAT slave servo/stepper drives and motors, EtherCAT slave I/O modules; from any supplier or mix of suppliers.

- Vision System: modular and self-contained vision system; cameras, vision processor, monitor.

- Robotic controllers.

The Motion Controller is the “brain”, vision system is the “eyes”, drives and motors are the “muscle”, robots are “other smart devices”, HMI is the “human command center” of the system. Communication between Motion Controller and EtherCAT drives and IO is via EtherCAT,. Communication between the Motion Controller, Vision Systems, Robots are via Ethernet/IP. IoT connection to Internet is via MQTT over standard Ethernet. With these configurable components designed as a state of art Industry 4.0 technology, the Oracle Robotics Motion Control Solutions platform can be customized for any machine motion control application.

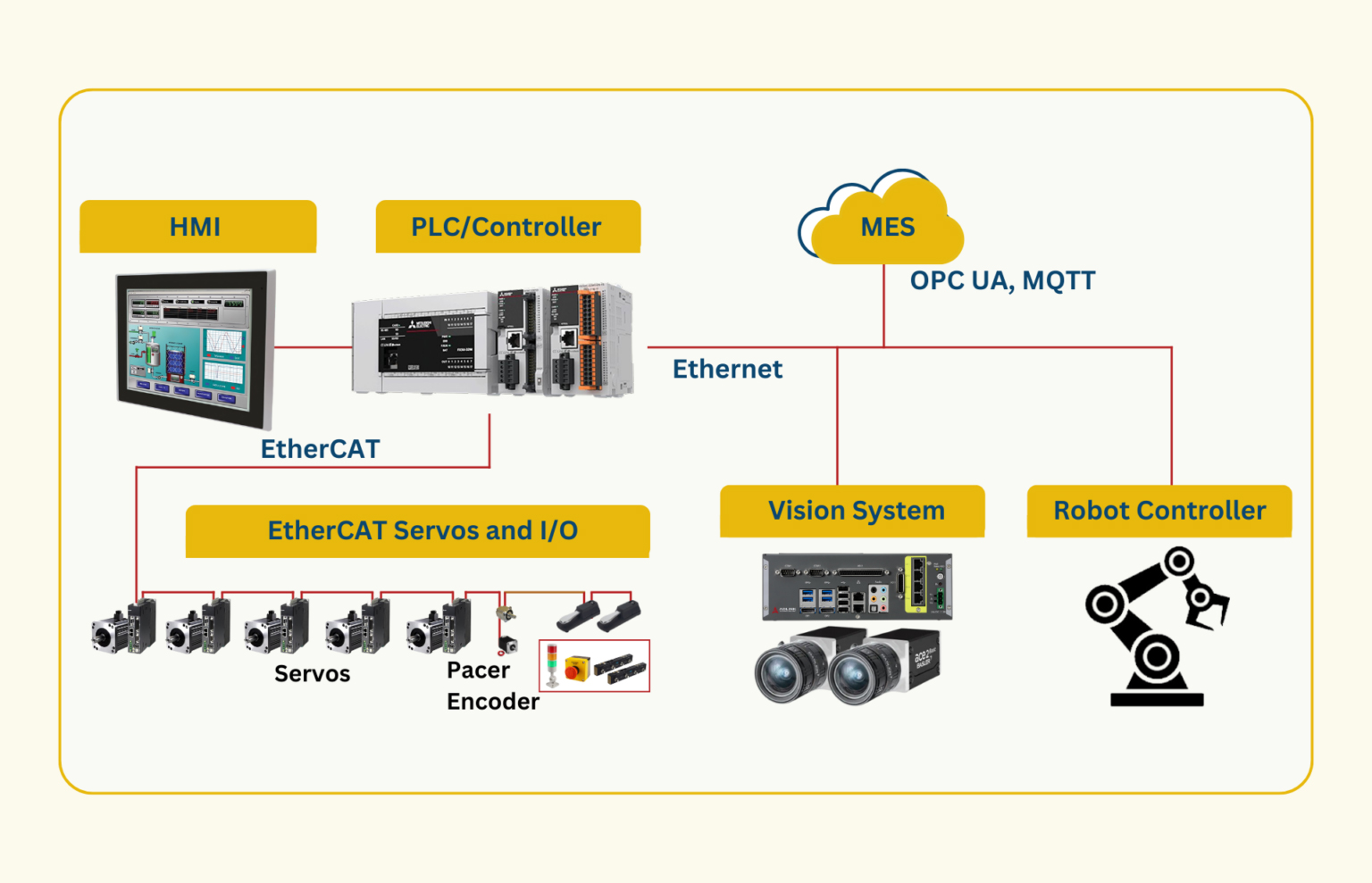

Motion controller is based on industrial PC, EtherCAT hardware and CODESYS/IEC 61131-3 software. Hardware and software are based on global open standards, benefiting from economies of scale, flexibility, expandability, rugged design, supplier independence. Any EtherCAT compatible servo drive and IO module can be added from any combination of suppliers.

Our software technology tightly integrates communication between the motion controller, vision systems and other robot controllers in the automation project. We provide tested software function blocks for all major vision system suppliers and industrial robots for real time communication.

The End-user can simply make choices to configure the communication Function Blocks, and plug-and-play to implement the tightly synchronized motion control communication.

The main fieldbus for high-performance motion control is EtherCAT. The hardware/software platform supports any of the major and minor fieldbus protocols, such as CANbus (CANopen, J1939), EtherNet/IP, Modbus, PROFINET and more.

Configuring the interface to each fieldbus is simply a few choices in GUI dialog windows. Application software is developed independent of the fieldbus communication protocol. Hence, the same application can be easily reconfigured to work with a different or additional fieldbuses.

Cloud connectivity is supported by OPC UA Server/Client model, where the PLC/Motion Controller with CODESYS Runtime provides the OPC UA Server functionality, as well as Web Server functionality. Then the factory floor controls can be accessed and monitored from the web, integrated into ERP/MES/SCADA management software tools at the higher level. This platform provides the option to control/monitor capability to even the simplest ON/OFF device on the automation cell from anywhere in the world via the Internet.

Motion Controller features include:

- Interface to any EtherCAT servo/stepper drive-motors and EtherCAT Slave I/O nodes from hundreds of global suppliers, up to 64 axis closed loop servo motion control in one EtherCAT cable network, controlled with as low as 100 microsecond loop update time, with up to 1024 additional I/O points via EtherCAT I/O modules.

- CODESYS application software development environment, IEC-61131-3 standard compliant, and CODESYS runtime, multi axis coordinated motion profiles to generate any path and trajectory: linear, circular, elliptical, polynomial, spline and PVT, electronic gearing and camming between axes, based on actual position or commanded position or any modification of these, rational number (numerator/denominator) gear ratio definition, registration mark/position capture based corrective position commands (super-imposed motion).

- Oracle Robotics provides robust and time-tested dependable motion control function blocks as library – key to effective development in performance and cost for any application. Oracle Robotics Motion Control Software Platform turns the industrial PLC hardware and CODESYS software into a “Motion Controller”: it defines project structure specific to the motion control technology and a host of motion control libraries. This is similar to a Laptop PC with Windows (analogous to CODESYS) and add Visual Studios which provide application specific project framework and large selection of libraries.